From Cloudy Water to Crystal-Clear Ice: Why Water Treatment Defines Ice Plant Success

Ice quality matters for health and safety

Ice needs to be safe for consumption. In the Philippines, it’s used in wet markets, groceries, and butchers to keep meat and produce fresh. When it’s meant to be added to beverages, whether sold in convenience stores or used in restaurants, the ice must pass the Philippine National Standard for Drinking Water.

Dirty ice results in health and safety issues. Ice that is not safe for consumption is from water that has:

- Bacteria. Pathogens like E. coli and Salmonella can survive freezing temperatures and infect consumers. Food-borne illnesses from contaminated ice can cause diarrhea or stomach cramps.

- Pesticides. In agricultural areas, pesticides and fertilizers can leach into groundwater. They are harmful when ingested, and trace amounts mean non-compliance with food-grade standards, resulting in failed laboratory tests.

- Iron and other dissolved solids. These contaminants make the ice look yellow and cloudy; and consumers consider murky ice unsafe. Iron in small amounts may not be harmful to one’s health, but it feeds bacteria that can cause issues.

For businesses, a single incident of unsafe ice can damage their reputation and lead to regulatory penalties. For ice plants specifically, providing dirty ice poses problems to hotels, restaurants, and other partners that require strict water quality compliance; it would lower customer trust.

Furthermore, because Philippine groundwater is rich in calcium and magnesium ions and silica, the resulting ice can not only fail food safety standards but also reduce the efficiency of ice machines. The calcium and magnesium ions cause scaling inside ice makers, evaporators, and condensers. Over time, the scaling clogs nozzles and water lines, which reduces output, shortens equipment lifespan, and increases maintenance costs.

Silica also causes scaling; it forms a glassy, film-like layer that standard descaling chemicals cannot easily dissolve. It often requires a more specialized chemical treatment or even physical scraping to remove, which increases labor costs.

Pure water means pure ice

Ice plants must treat their water to produce food-grade ice that satisfies their customers. At Aquasafe, our water treatment process can include:

- Chlorination. This step is essential if the water has bacteria and other microorganisms. It disinfects the water and ensures microorganisms don’t multiply.

- Pretreatment filtration modules, including activated carbon. These remove pesticides, iron, suspended solids, and chlorine to protect the reverse osmosis membranes. Carbon has a large surface area that adsorbs these molecules, effectively removing them from the water.

- Chemical dosing to treat silica and water hardness and prevent machine damage.

- Reverse osmosis system. This removes total dissolved solids (TDS), including salts, minerals, and leftover contaminants.

- UV sterilization to further safeguard against microbes before water is frozen to ice.

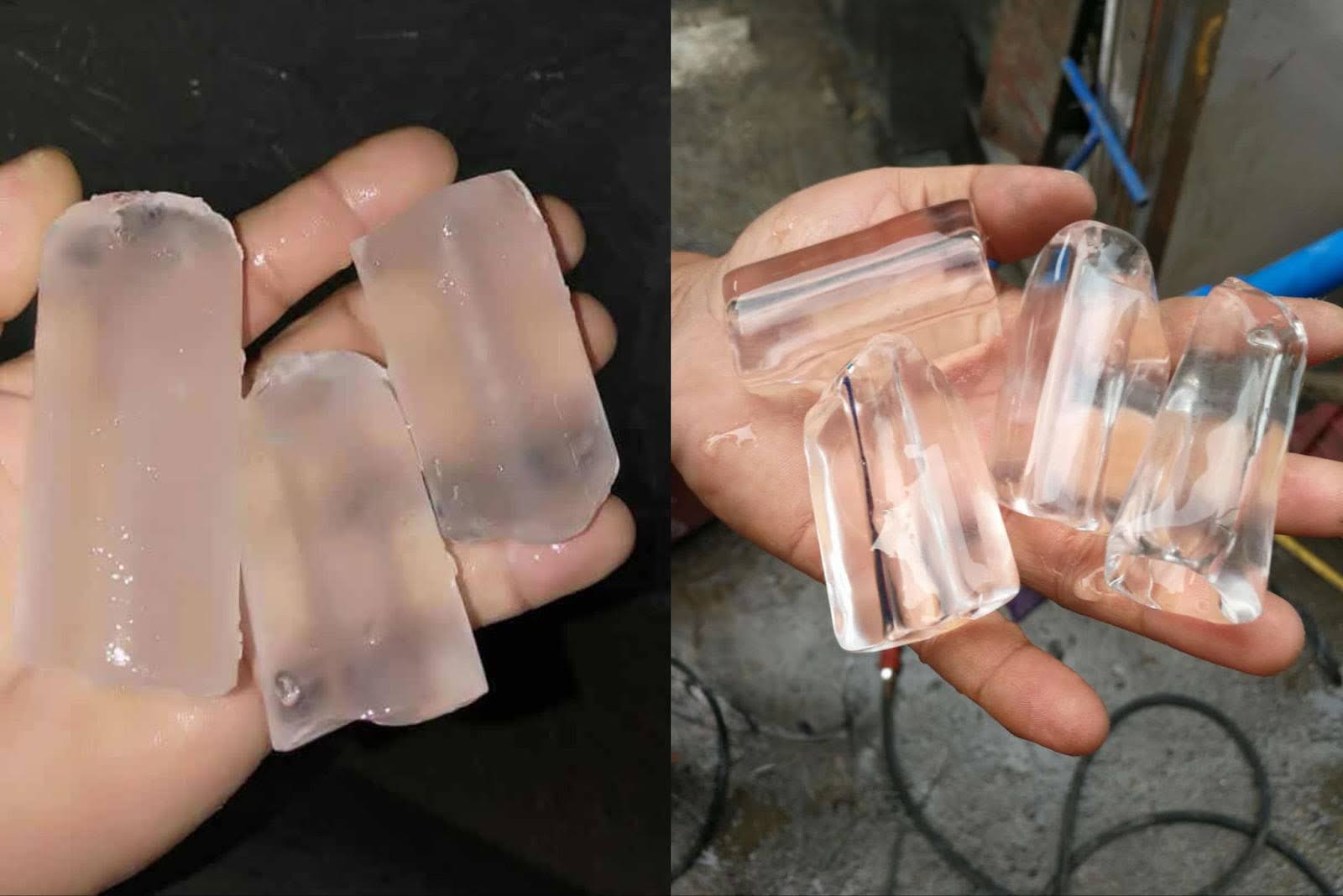

Depending on their clientele, ice plants may or may not need crystal-clear ice. Ice plants that produce ice for wet markets, butcheries and meat processors, and storage coolers only require ice that is clean and safe—not necessarily crystal-clear. For cooling or food preservation, the ice is often white or cloudy but free of harmful contaminants. Meanwhile, ice plants that supply ice to hotels, dining establishments, and convenience stores need crystal-clear, safe ice because the presentation also matters in the context of consumption.

For ice plants that need crystal-clear ice, we install a reverse osmosis system to remove all minerals, which add a yellow or brown color to the ice. On the other hand, we recommend regular filtration and UV sterilization to ice plants that seek to fulfill the bare minimum food and water safety requirements. We at Aquasafe tailor-fit the water treatment system to meet our clients’ various requirements.

Our clients in the ice production business yield crystal-clear, safe ice that passes tests and is compliant with food and water standards set by the Department of Health. Because scaling and clogs are avoided, ice machines remain reliable and production is consistent. Improving their reputation on the market also maintains customer trust and boosts their sales.

For the right water specifications for your business or other inquiries, contact Aquasafe at inquiry@aquasafe.com.ph